1 Diyaarso ka hor kulanka

1.1Hubi in isku xirka flange ee loo doortay sida ISO 6162-1 uu buuxiyo shuruudaha codsiga (tusaale cadaadiska la qiimeeyay, heerkulka iwm.).

1.2Hubi in qaybaha flange (xidhiidhiyaha flange, xajin, fur, O-ring) iyo dekeduhu waafaqeen ISO 6162-1

1.3Hubi furayaasha saxda ah, mitirka nooca 1 iyo inch ee nooca 2.

1.4Hubi ha ku darin qaybaha iyo qaybaha ISO 6162-2.Sida loo garto arka kala duwanSida loo aqoonsado ISO 6162-1 iyo ISO 6162-2 isku xirka flange iyo qaybahaisku xidhka

1.5Hubi in dhammaan shaabadeynta iyo is-dhexgalka dusha sare (ay ku jiraan dekedda iyo qaybaha flange) ay ka xor yihiin burs, nicks, xagashada iyo wax kasta oo shisheeye ah.

2 Sida saxda ah ee la isugu keeno

2.1Si loo yareeyo xoqitaanka O-ring, ku subag O-ring jaakad fudud oo ah dareeraha hydraulic ee loo isticmaalo nidaamka ama saliid ku habboon, marka loo baahdo.Si gaar ah u taxaddar, maadaama saliidda xad-dhaafka ah ay ka soo bixi karto kala-goysyada oo ay horseedi karto calaamad been ah oo daadsan.

Fiiro gaar ah:Cabbirrada O-ring waxay eegtaa miiska 1 ama miiska 2, waxayna la mid tahay cabbirka metric ama inch skru, waxay la mid tahay ISO 6162-1 iyo ISO 6162-2 isku xirka flange, ma jiraan arrin isku dhafan.

2.2Dhig madaxa bararka leh iyo xajinta garabka.

2.3Ku dheji weeliyeyaasha adag ee birta, oo geli furayaasha dhexda godadka xalalka.

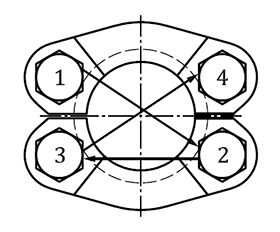

2.4Gacanta ku adkee boolalyada isku xigxiga ee lagu muujiyey Jaantuska 1 si aad u hubiso xidhiidhka isku midka ah ee dhammaan afarta goobood ee furaha si aad uga hortagto cirifka garabka, kaas oo u horseedi kara jabka bararka inta lagu jiro codsiga wareegga ugu dambeeya.

Jaantuska 1 - Isku xigxiga isku dhufashada

2.5Turjuc furayaasha isku xigxiga ee sawirka 1 ka muuqda laba ama in ka badan oo kordhay ilaa heerka wareegtada lagu taliyey iyo adeegsiga cabbirada furaha ee shaxda 1 ee metric screw iyo miiska 2 ee furka inch.

Shaxda 1 - Cabbirrada qulqulka iyo furaha oo leh muraayad mitir ah oo loogu talagalay isku xirka flange ee waafaqsan TS EN ISO 6162-1

| Magac ahaan cabbirka | Ugu badnaan shaqaynaysa cadaadis | Nooca 1 (metric) | ||||||||

| Isku-xidhka Isku-xidhka | Dhererka furka mm | Qulqulka qulqulka N.m | Fure | O- giraanta | ||||||

| MPa | bar | hexagon madaxa ku duub mm | godka madaxa ku duub mm | Code | Idhexroorka mm | CRoss - qaybta mm | ||||

| 13 | 35 | 350 | M8 | 25 | 32 | 13 | 6 | 210 | 18.64 | 3.53 |

| 19 | 35 | 350 | M10 | 30 | 70 | 16 | 8 | 214 | 24.99 | 3.53 |

| 25 | 32 | 320 | M10 | 30 | 70 | 16 | 8 | 219 | 32.92 | 3.53 |

| 32 | 28 | 280 | M10 | 30 | 70 | 16 | 8 | 222 | 37.69 | 3.53 |

| 38 | 21 | 210 | M12 | 35 | 130 | 18 | 10 | 225 | 47.22 | 3.53 |

| 51 | 21 | 210 | M12 | 35 | 130 | 18 | 10 | 228 | 56.74 | 3.53 |

| 64 | 17.5 | 175 | M12 | 40 | 130 | 18 | 10 | 232 | 69.44 | 3.53 |

| 76 | 16 | 160 | M16 | 50 | 295 | 24 | 14 | 237 | 85.32 | 3.53 |

| 89 | 3.5 | 35 | M16 | 50 | 295 | 24 | 14 | 241 | 98.02 | 3.53 |

| 102 | 3.5 | 35 | M16 | 50 | 295 | 24 | 14 | 245 | 110.72 | 3.53 |

| 127 | 3.5 | 35 | M16 | 55 | 295 | 24 | 14 | 253 | 136.12 | 3.53 |

Shaxda 2 - Cabbirrada qulqulka iyo furaha leh furka inch ee isku xirka flange ee waafaqsan TS EN ISO 6162-1

| Magac ahaan cabbirka | Ugu badnaan shaqaynaysa cadaadis | Nooca 2 (inji) | ||||||||

| Isku-xidhka Isku-xidhka | Dhererka furka mm | Qulqulka qulqulka N.m | Fure | O- giraanta | ||||||

| MPa | bar | hexagon madaxa ku duub in | godka madaxa ku duub in | Code | Idhexroorka mm | CRoss - qaybta mm | ||||

| 13 | 35 | 350 | 5/16-18 | 32 | 32 | 1/2 | 1/4 | 210 | 18.64 | 3.53 |

| 19 | 35 | 350 | 3/8-16 | 32 | 60 | 9/16 | 5/16 | 214 | 24.99 | 3.53 |

| 25 | 32 | 320 | 3/8-16 | 32 | 60 | 9/16 | 5/16 | 219 | 32.92 | 3.53 |

| 32 | 28 | 280 | 7/16-14 | 38 | 92 | 5/8 | 3/8 | 222 | 37.69 | 3.53 |

| 38 | 21 | 210 | 1/2-13 | 38 | 150 | 3/4 | 3/8 | 225 | 47.22 | 3.53 |

| 51 | 21 | 210 | 1/2-13 | 38 | 150 | 3/4 | 3/8 | 228 | 56.74 | 3.53 |

| 64 | 17.5 | 175 | 1/2-13 | 44 | 150 | 3/4 | 3/8 | 232 | 69.44 | 3.53 |

| 76 | 16 | 160 | 5/8-11 | 44 | 295 | 15/16 | 1/2 | 237 | 85.32 | 3.53 |

| 89 | 3.5 | 35 | 5/8-11 | 51 | 295 | 15/16 | 1/2 | 241 | 98.02 | 3.53 |

| 102 | 3.5 | 35 | 5/8-11 | 51 | 295 | 15/16 | 1/2 | 245 | 110.72 | 3.53 |

| 127 | 3.5 | 35 | 5/8-11 | 57 | 295 | 15/16 | 1/2 | 253 | 136.12 | 3.53 |

Waqtiga boostada: Jan-20-2022